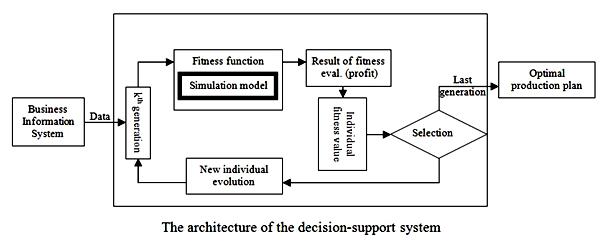

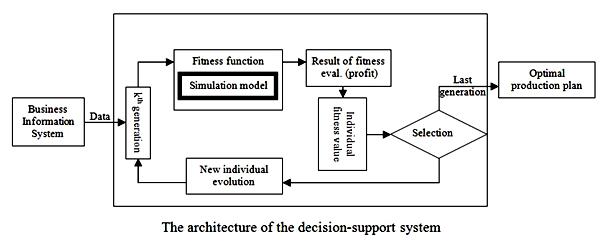

This project represents an approach in using simulation models and genetic algorithms for generating an aggregative production plan to maximize the total profit of the firm. A simulation model will be used for fitness function computation of genetic algorithm results. The described methodology provides a tool which assists the company management in decision which of the suitable solutions will become the production plan. The entire system is composed by a business information system - a database filled with data from the main ERP system of the company, a simulation model and a genetic algorithm. The purpose of the integrated system is to help operative management personnel to take decisions with respect to production planning and marketing strategies.

Genetic algorithms (GA) are a very effective tool that enables solving complicated practical optimization problems. An important characteristic of genetic algorithms is their simplicity and versatility. The principal advantage of GAs is their inherent ability to intelligently explore the solution space from many different points simultaneously enabling higher probability for locating global optimum without having to analyze all possible solutions available and without requiring derivatives (or numerical approximations) or other auxiliary knowledge. Their main drawback is a long calculation time. A solution to this problem is parallelizing genetic algorithms.

Most real life optimization and scheduling problems are too complex to be solved completely. The complexity of real life problems often exceeds the ability of classic methods. In such cases decision-makers prepare and execute a set of scenarios on the simulation model and hope that at least one scenario will be good enough to be used as a production plan. A long time goal for scheduling optimization research has been to find an approach that will lead to qualitative solutions in a relatively short time. The development of decision-making methodologies is currently headed in the direction of simulation and search algorithm integration. This leads to a new approach, which successfully joins simulation and optimization. The proposed approach supports man-machine interaction in operational planning.

The optimization in our system is based on a genetic algorithm which uses an original co-mutation operator called LR-Mijn, capable of operating on a set of adjacent bits in one single step. Chromosome fitness is calculated with a fitness function. After being evaluated with a fitness function, each chromosome in population receives its fitness value. In fact, the simulation model represents the implementation of the fitness function of the genetic algorithm, needed in the genetic algorithm to evaluate each member (chromosome) of the population.

The probability to select a certain chromosome (possible production plan) in the next generation is related with its performance in simulated conditions (the profit provided by the simulation model). That profit determines the fitness value of the respective possible solution of our optimization problem

The value of the fitness function is computed by the simulation model, with uses the respective chromosome as input data. The value returned from the simulation model is used to evaluate that chromosome, which encode a possible production plan.

By applying the genetic operations on the members of a population of decisional rules at the moment t, it results a new population of rules that shall be used at the moment t+1. The population from the initial moment, t = 0 is generated randomly and the genetic operations are applied iteratively until the moment T (at which the condition for stopping the algorithm is accomplished).

The above iterative process may be interpreted economically as it follows. The evolution process has as objective the finding of the successful individuals. The binary strings of these individuals (chromosomes) with high fitness values (a high profit) will be the basis for building a new generation (population). The strings with lower fitness values, which represent decisions to produce with a low profit, find few imitators (or none) in the following generation.

Companies need to be flexible to compete for the market share and adapt to market demands by offering competitive prices and quality. This calls for a wide assortment of products or product types, small production costs, etc. Simulation is a strong interactive tool that helps decision-makers improves the efficiency of enterprise actions. The ability of simulation to show a real process on the computer with the consideration of uncertainty is a big advantage when analyzing system behavior in complex situations.

The purpose of the integrated system is to aid operative management personnel in production planning and marketing strategies (incorporated in simulation model). The main advantage of the presented system is to enhance man-machine interaction in production planning, since the computer is able to produce several acceptable production plans using the given data and a set of criteria. The planner then selects the most suitable production plan and modifies it, if necessary.

After completion of the optimization process, the most suitable production plans are simulated on the visual model of the system. Using chosen parameters and according to defined criteria, the decision-maker is motivated to search for results which will have the most advantageous influence on the whole production process. The result, which is selected after simulation on the visual simulation model, becomes the proposed production plan.

Because the GA-SIM system is implemented in Java as main language, was necessary a bridge between Java code and the simulation model, implemented in Excel. Our choice for this purpose was JExcelAPI ( http://jexcelapi.sourceforge.net/ ), a mature, open source java API enabling developers to read, write, and modify Excel spreadsheets dynamically.

|